Welcome to the official website of Changzhou Nanji Magnetic Device Factory

-

Call Us Today

(86) 519-83208039

-

Working Hours

9 am to 6 pm

-

Xinbei District, Changzhou

No. 2 Xie Road

Ndfeb magnet

1. Product name: ndfeb magnet

2. Product introduction:

NdFeB permanent magnets are mainly used in micro-motor, permanent magnetic instrument, electronic industry, automobile industry, petrochemical industry, nuclear magnetic resonance device, audio equipment, magnetic suspension system, magnetic transmission mechanism and magnetic therapy equipment. They can also be used for oil circuit magnetization of motorcycles and automobiles to achieve the purpose of fuel saving.

Rare earth permanent magnet NdFeB (NdFeB) is the most powerful permanent magnet in modern magnets. It not only has high remanence, high coercivity, high magnetic energy product, high performance-price ratio and other characteristics, but also is easy to be processed into various sizes. It has been widely used in aviation, aerospace, electronics, electroacoustics, electromechanical, instruments, meters, medical technology and other devices requiring permanent magnetic field, especially in the development of high-performance, miniaturization Various lightweight products.

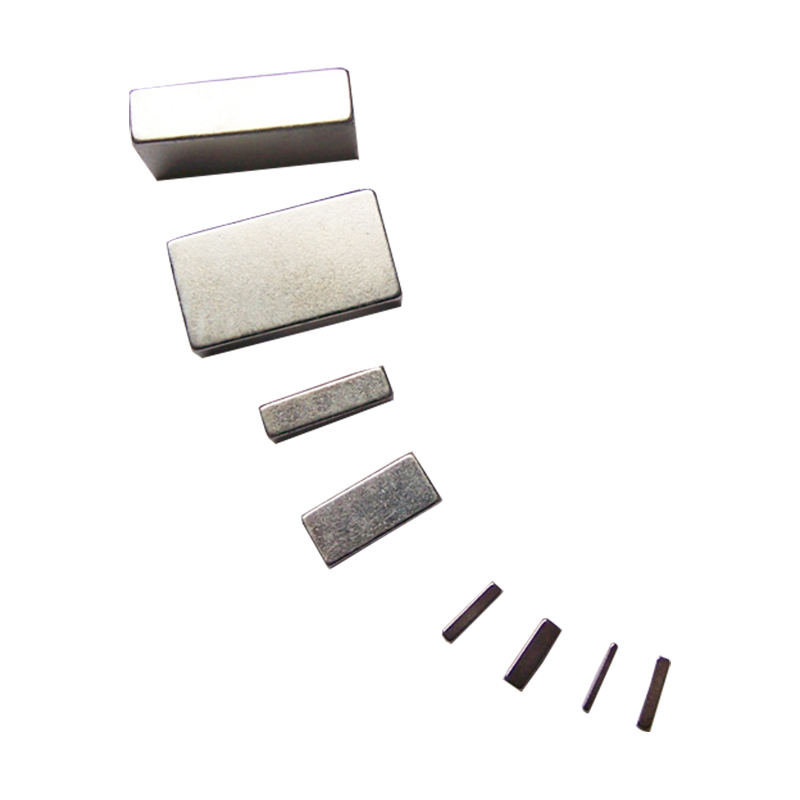

Our factory specializes in producing various kinds of permanent magnetic materials with complex shape, inclined plane/side, small size and high precision. The processing equipment is complete. In addition to producing square, cylindrical, round, spherical and other conventional products, it has great advantages in the processing of special-shaped and micro-shaped magnets.

3. Material grade

N35 -- N50, 33M -- 48M, 30H -- 45H, 27SH -- 45SH, 25UH-40UH, 23EH -- 38EH

4. Operating temperature

80-200(℃)

5. Product characteristics: very hard and brittle

High diamagnetism

Without proper coating or electroplating, the corrosion resistance of the material is low

High cost/performance ratio

General temperature stability

Not suitable for high operating temperature environmen

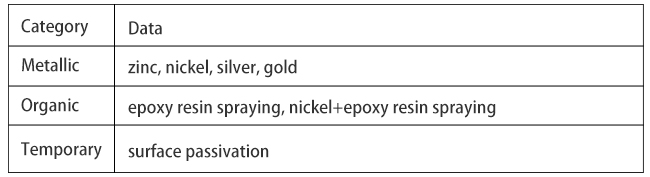

6. Surface treatment:

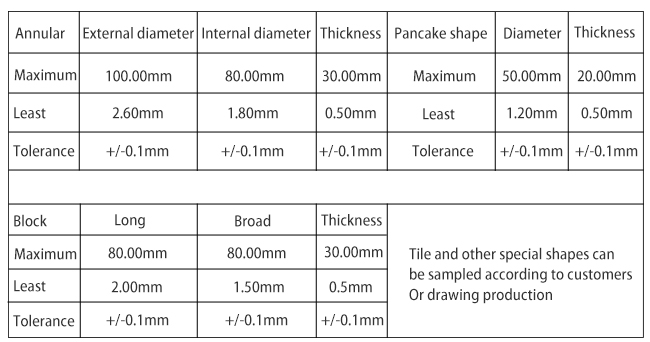

7. Dimensional tolerance